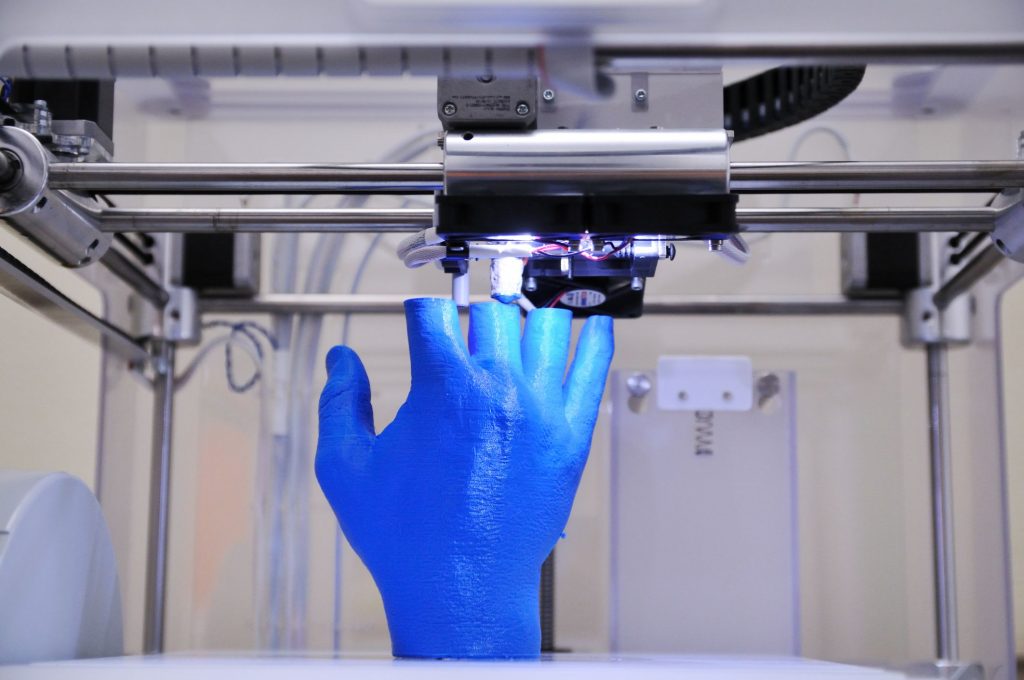

A prosthetic limb. Healthy tissue. A lifelike model of an internal organ.

All from a printer.

The impact of 3D imaging already is having an impact on the automotive and aerospace industries, among others. Its biggest impact, though, may be on healthcare, where it could improve outcomes, lower costs and save lives.

Mike Thoma of Travelers Global Technology believes “3D printing has the potential to change the way we produce and deliver physical products, the same way the internet changed the way we interact with information.”

Speaking to Becker’s Hospital Review, Thoma pointed out that 3D printing already is being used to produce items such as hearing aids and prosthetic limbs that are “made to an individual patient’s exact body shapes and contours, often at a fraction of the cost of a conventional medical device.”

Other 3D printing innovations include skin for burn victims and splints for babies with the condition, tracheobronchomalacia, that causes airways around their lungs to collapse.

According to Harvard Business Review, the splints are the first 3D implant for children and are designed to grow with the child. Furthermore, the splints can be produced in a few hours at a cost of $10 each. They are biodegradable, meaning they will disappear as children recover from the condition and no longer needs them.

Among 3D printing’s other healthcare feats:

- Models that allow surgeons to plan and practice an operation before cutting

- Facial reconstructions

- Implants to replace arthritic knees and other joints

- Images of small children and infants more accurate and detailed than an MRI

Further, human organs may soon be replicated by 3D imaging. Researchers are attempting to create artificial organs that the body will accept. This technology would revolutionize organ transplants as patients would no longer have to wait for a donor. Also, sensors embedded in the printed organs would provide data that allows physicians to track a patient’s recovery. These organs could be custom-fitted to patient’s anatomy and designed to perform even better than an organic organ.

As amazing as what can be produced with a 3D printer, the fact that it can be done at far less expense than traditional methods may prove to be just as important.

The U.S. spends nearly 18% of its gross domestic product on healthcare, almost twice as much as any other industrialized nation. However, a 2017 Commonwealth Fund study rated U.S. healthcare last among 11 developed nations. Making healthcare more accessible, more affordable and more effective is vital to improving those numbers, and 3D imaging could be part of the solution.

The technology behind 3D imaging helps make it cost-effective. Objects are built from a digital model, with successive layers of material added until the desired form is reached. The digital model ensures precision and decreases chances of error. And where older manufacturing techniques involve removing material, for example by cutting or drilling which creates waste, 3D imaging builds by adding precise amounts of materials from a digital model.

The marvels of 3D imaging may seem like science fiction today, but they are proving to be very real and have the potential to be massively transformative in U.S. healthcare in the near future.